Gas-powered engines have over 1,000 parts, while new electric engines have about 50. This significant difference in complexity translates to fewer job opportunities as EVs are simpler and easier to assemble, therefore there is a workforce reduction to make EV’s

Despite the extensive coverage on the rise of electric vehicles since 2019, there has been surprisingly little focus on the impending radical and painful transformation of the industry.

- Last week, workers at GM, Ford, and Stellantis went on strike.

- This work stoppage will worsen the structural advantage that Tesla, the leader in electric vehicles (EVs), already enjoys.

- EVs have fewer components compared to gas-powered vehicles, resulting in fewer job opportunities in the industry.

For decades, the auto industry has been a major job creator, providing stable incomes for millions of workers and their families. However, as EVs surpass traditional vehicles, this scenario will change. The destruction of jobs in this industry is inevitable, far surpassing the impact of AI.

‘Reduced Workforce’

A few years ago, the Congressional Research Service, which offers analysis to US legislators, issued a warning. Gas-powered vehicles have powertrains with up to 2,000 components, while Tesla stated that its drivetrain consists of just 17 moving parts, including 2 in the motor.

The Congressional Research Service elaborated, “Electric vehicle powertrains, if built domestically and not imported, would generate production employment, but fewer employees may be needed than at present because vehicle battery packs have relatively few components and are less complicated to assemble than internal combustion engine powertrains. Electric vehicles utilize a large number of electronic sensors, but these devices require little labor to produce and assemble.”

The cost of labor is a significant factor in competition among companies. Whenever a business possesses a clear cost advantage, other companies quickly adopt a similar strategy.

Tesla had a ten-year headstart in EV manufacturing, but other automakers are now racing to catch up. While there may be environmental benefits to EVs, their more efficient manufacturing process is a major driving force.

A 40% Workforce Reduction to make EV’s

Auto executives tend to avoid discussing this topic openly, as it implies job losses. Nevertheless, some industry leaders have occasionally addressed it.

In late 2022, Ford CEO Jim Farley mentioned to the Financial Times that manufacturing EVs requires a workforce reduction to make EV’s, 40% less labor than producing the same number of internal combustion vehicles. In 2019, VW’s CEO estimated that building EVs involves about 30% less effort compared to gas-powered cars.

Carl Court/Getty Images

The UAW strike could result in a loss of up to $5 billion for America’s three main traditional automakers within just 10 days. This will further magnify the structural disadvantage they already face.

Elon Musk’s Early Victory

Regardless of the outcome of the strike, Tim Higgins, one of the top auto industry reporters, argues that Elon Musk has already emerged as the victor. In his recent article for The Wall Street Journal, Higgins explains how Tesla developed a more efficient vehicle manufacturing process.

Unlike GM, Ford, and Stellantis, Tesla, as a pure EV manufacturer, avoids the complexities of internal combustion engines, gas lines, exhaust pipes, and other intricate designs that increase assembly costs and has embraced the workforce reduction to make EV’s.

Although GM, Ford, and Stellantis have started producing more EVs, their operations are still relatively small. Consequently, they mostly incur losses by selling these new vehicles. The majority of their operations remain focused on gas-powered cars and trucks.

Tesla’s workforce is not unionized, enabling the company to continue producing Model 3s, Model Ss, Model Ys, and soon the new Cybertruck, while some factories of its major US competitors remain idle.

Tesla

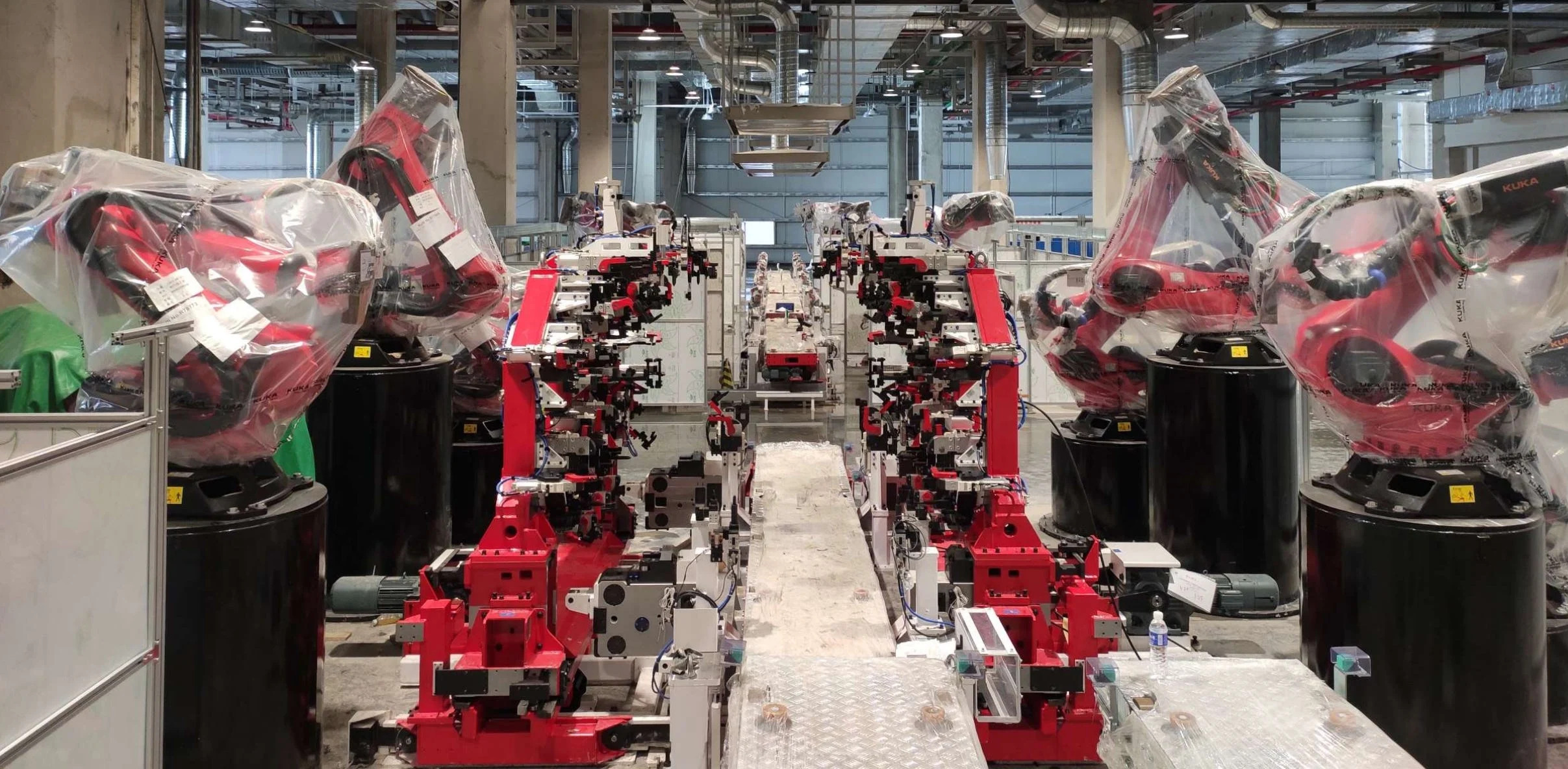

The Giga Press

Tesla is not slowing down, but rather aiming to further extend its manufacturing advantage. The company recently introduced Gigacasting technology to its auto plants.

The Tesla Giga Press is a massive machine that utilizes aluminum die casting to produce larger vehicle parts. Once again, the objective is to reduce the number of car parts, simplifying and enhancing the manufacturing process. However, this also implies a reduction in job opportunities.

According to Reuters, Toyota, GM, Hyundai, and China’s Geely are also beginning to use or plan to use this technology.